Technologies & Applications > Level sensing

Level sensing

A variety of level sensing technologies are available. Here we explain the typical applications and benefits of each.

To further help you select the correct sensing technique for your media RS and Mobrey, a level sensing specialist, have created an interactive guide.

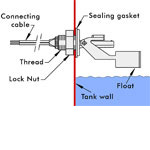

Access the interactive level sensing product selectorFloat switches

- Various formats available - top & side mount, cable and submerged

- Basic full/empty type level indication set by mounting position

- Cost effective and simple to install

- Often can't switch inductive loads directly - use interface relay

- Float material to liquid compatibility must be checked

Capacitive level switches

- Barrel (side mount) and probe (top mount) formats

- Basic full/empty type level indication set by mounting position

- Accurate switching even with heavy residue build-up

- High reliability due to no moving parts

- Can often be used with liquids and powder or granular product

Vibrating level probes - Squings

- Uses high frequency vibrations which are damped by product contact to sense level

- Fork and road designs available to suitable media

- Basic full/empty type level indication set by mounting position

- Very reliable, with self-monitoring features built-in

- Sensing of liquids, pastes, grains, powders, sand and other granular products possible

Conductive level switches

- Uses stainless steel probes (1m) to provide sensing for up to 3 switch points

- Can only be used with conductive fluids

- Used in conjunction with a level control relay to set & monitor switching points

- Once installed switching points can be easily adjusted via relay controls

Learn more about the VEGACON 66 combined unit

Ultrasonic level sensors

- Ultrasonic sound pulses are reflected by the surface of the liquid

- Non-contact level sensing of water, emulsions, oils, chemicals and effluent

- Provides proportional indication of level via a 0/4-20mA or 0-10V output

- Typical range 0.25 to 10m

- Provides accurate level indication, but can be affected by dust or foam

- Can be used with solids, but range reduced by 50%

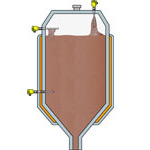

Microwave level sensors

- Uses microwave pulses that reflect of the surface - similar to radar

- Available in guided or con-contact versions

- Suitable for use with any liquid, and most solids

- Unaffected by dust, foam, vapours, pressure or product build-up

- Provides proportional indication of level via a 0/4-20mA

- Typical range 0.15 to 30m

Pressure based level sensors

- Provides level measurement in tanks by using head pressure

- Suitable for water, oil, fuels and most industrial liquids

- Can only be used in non-pressurised tanks or containers

- Good level of accuracy - 0.1 to 0.2%

- Provides proportional indication of level via a 0/4-20mA output

- Submersible and tank mount versions available

See our range of tank mount level sensors